mar 27, 2018 | News

[vc_row][vc_column][vc_column_text]The company DCR Sp. z o.o. organizes EASTER PLASTIC COMPETITION intended for children of our employees. All works should:

- refer to the upcoming Easter

- include an element associated with DCR Sp. z o.o. (e.g. logo or a company product)

- made with any technique should not exceed A4

Please submit your works in the office or at the manager. The deadline for submitting works is 26/03/2018 (Monday).

The results of the competitions will be announced on March 29, 2018 (Holy Thursday).

The authors of the best works will receive ATTRACTIVE AWARDS.

[/vc_column_text][vc_media_grid element_width=”6″ grid_id=”vc_gid:1522160292852-6a2eea86-20dd-9″ include=”1325,1326,1327,1328,1343″][/vc_column][/vc_row]

mar 26, 2018 | News

[vc_row][vc_column][vc_column_text]

Let this Easter be full of hope and faith,

Let the Risen Christ bring spring flowers, joy, love, peace and happiness.

Warm, full of joyful hope of the Resurrection of the Lord,

family warmth, joyful meetings at the Easter table and a tasty blessed egg

wish

Management and Employees of DCR Sp. z o.o.

[/vc_column_text][/vc_column][/vc_row]

[/vc_column_text][/vc_column][/vc_row]

sie 8, 2017 | News, News

[vc_row][vc_column][vc_single_image image=”1222″ img_size=”full” alignment=”center” image_hovers=”false”][ultimate_spacer height=”30″][vc_column_text]

Continuously implementing the DCR vision as a modern and environmentally friendly company we have decided to modernize the car fleet. As a result, two new truck sets have been purchased to replace worn out vehicles carrying IBCs and steel drums. The manufacturer of cars is DAF (http://www.daftrucks.pl/pl-pl#), while the builder of curtain covers and trailers is our permanent partner – the company Gniotpol (http://gniotpol.pl/). It can now be said that the compromise reached between payload and cargo space (limited by statutory external dimensions) is successful. We are still able to transport up to 60 pieces of IBC or 300 steel drums in one transport, while a significant change compared to previously used transport units is to increase the payload of new sets.

[/vc_column_text][ultimate_spacer height=”30″][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”1224″ img_size=”full” alignment=”center” image_hovers=”false”][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”1223″ img_size=”full” alignment=”center” image_hovers=”false”][/vc_column_inner][/vc_row_inner][ultimate_spacer height=”30″][vc_column_text]

The DMC of one truck set is 26 tons, which in practice means the ability to carry almost 15 tons of cargo. It makes us mostly independent of external transportation, allowing for the transport of larger number of steel drums, without the risk of overloading, or transporting steel containers. It is also very important to have low emissions. New engines meet Euro 6 standards. Our new trucks are even more ecological because they emit 80% less harmful nitrogen oxides than Euro 5 trucks. Currently, not only reconditioned IBC containers or steel drums contribute to greenhouse gases reduction, but also means of transport we carry them.

[/vc_column_text][/vc_column][/vc_row]

cze 29, 2017 | News, News

[vc_row][vc_column][vc_single_image image=”1153″ img_size=”full” alignment=”center”][ultimate_spacer height=”33″][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_single_image image=”1157″ img_size=”full”][/vc_column][vc_column width=”2/3″][vc_column_text]

As of January 1, 2016, entrepreneurs who recycle packaging waste are required to carry out an annual external audit. The deadline for this obligation is 30 April of the year following the year in which it occurs.

The entry into force of these regulations means that 2016 was the first year audited. The new regulations concern companies that carry out recycling or other then recycling recovery process of packaging waste that issue DPO or DPR documents, as well as those who export packaging waste and companies carrying out intra-community deliveries of packaging waste that have issued EDPR or EDPO documents in a given calendar year. The audit can only be carried out by an accredited environmental verifier, ie EMAS accredited units. The scope of the annual audit includes, but is not limited to, checking permits, assessing the compatibility of the recovery process with those permits, assessing the technical capabilities of the recycler, and verifying the correctness and formality of the DPO, DPR, EDPO and EPDR documents issued.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][ultimate_spacer height=”33″][vc_column_text]Staying in line with the laws, DCR Sp. z o.o. underwent an external audit by selecting DNV GL as the partner of this operation, a group established in 2013 but reaching its roots in 1864. In our opinion, international reach and many years of experience guarantee a reliable assessment.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text][dt_quote type=”pullquote” layout=”right” font_size=”H3″ animation=”none” size=”1″]The result of the audit is the report, which shows that DCR Sp. z o.o. conducts its business in a fair, transparent and fully compliant manner.[/dt_quote][/vc_column_text][ultimate_spacer height=”33″][ultimate_spacer height=”33″][/vc_column][/vc_row]

maj 30, 2017 | News, News

[vc_row][vc_column][vc_single_image image=”1124″ img_size=”full” alignment=”center”][ultimate_spacer height=”33″][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][ultimate_spacer height=”17″][vc_single_image image=”1131″ img_size=”full”][/vc_column][vc_column width=”2/3″][vc_column_text]At the turn of the previous and current year in our company we have changed the varnishing technology in the reconditioning process of 200-litre steel drums. By introducing new eco-friendly paints and modern two-zone drying line with the cooling tunnel we have made a major step towards obtaining the highest quality of our products.

But we do not stop at this point. Last month we have introduced further solutions in order to achieve this goal. So far used spray application method (customer logo on reconditioned drums) we have replaced with the screen printing technique.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][ultimate_spacer height=”33″][vc_column_text][dt_quote type=”pullquote” layout=”right” font_size=”H3″ animation=”none” size=”1″]Such technology of printing is used by manufacturers of new cylindrical packagings, including, obviously, manufacturers of steel drums[/dt_quote][/vc_column_text][ultimate_spacer height=”33″][ultimate_spacer height=”33″][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text]Thanks to this technology, we can practically produce every design of a logotype and meet the expectations of our clients by offering reconditioned packagings but of a high quality and the standard close to the new product. At the same time, we do not forget about our philosophy of running a business in which ecology and environmental protection are of great importance.

Therefore, also in this project, we put a strong emphasis on these aspects. That’s why we have invited to cooperation suppliers who guarantee the materials of relevant characteristics and during the printing process we use ecological paints that do not contain PCV and formaldehydes.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_single_image image=”1135″ img_size=”full” alignment=”right”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][ultimate_spacer height=”33″][vc_single_image image=”1121″ img_size=”full”][/vc_column][vc_column width=”1/2″][ultimate_spacer height=”33″][vc_single_image image=”1122″ img_size=”full” alignment=”right”][/vc_column][/vc_row]

mar 30, 2017 | News, News

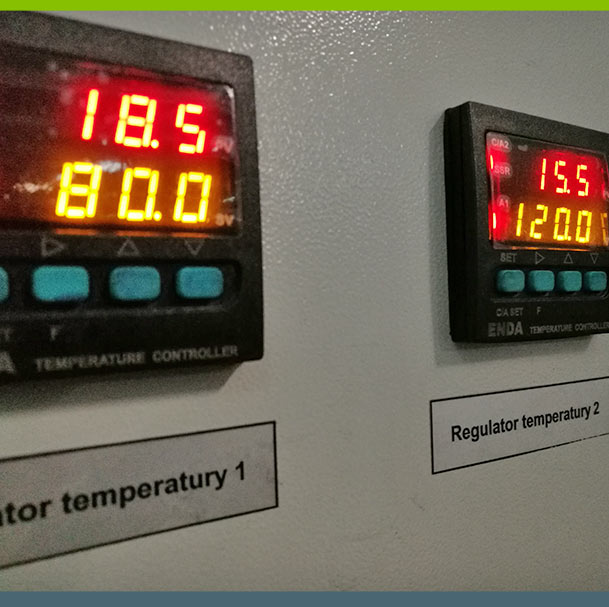

[vc_row][vc_column][vc_single_image image=”1096″ img_size=”full” alignment=”center”][ultimate_spacer height=”33″][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_single_image image=”1079″ img_size=”full”][/vc_column][vc_column width=”2/3″][ultimate_spacer height=”15″][vc_column_text]Staying faithful for image of the environmentally friendly company, the DCR Board decided in mid-2016 to change the technology used at the paint shop at our plant in Wola Krzysztoporska. One of the segments of activity of Drum Clean Recycling Sp. z o.o. is the recycling of steel drums.

This is a multi-stage process involving the regeneration of the bottom and the drum’s side, quality control and the application of a new paint coating in the color preferred by the customer.

A large amount of remanufactured drums results in significant consuming paints.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][ultimate_spacer height=”33″][vc_column_text][dt_quote type=”pullquote” layout=”right” font_size=”H3″ animation=”none” size=”1″]The new paint coating is now made in the technology used by the manufacturers of new drums[/dt_quote][/vc_column_text][ultimate_spacer height=”33″][ultimate_spacer height=”33″][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text]Previously used paints were the cause of VOC emissions, which, although consistent with the emission decision, in the opinion of the Management Board was incompatible with the ecological goals of our organization. New ecological paints are much more environmentally friendly and thus better fit into our long-term strategy.

However, they require a high drying / baking temperature up to 220 degrees Celsius. Therefore, implementing the project of technology changing we have purchased a professional two-zone drying line with a cooling tunnel.

A step in this direction in addition to expressing concern for the environment will allow us to offer our customers the highest quality product.[/vc_column_text][/vc_column][vc_column width=”1/3″][ultimate_spacer height=”15″][vc_single_image image=”1078″ img_size=”full” alignment=”right”][/vc_column][/vc_row][vc_row][vc_column][ultimate_spacer height=”33″][ultimate_spacer height=”33″][vc_column_text]

See the photo gallery

[/vc_column_text][ultimate_spacer height=”33″][dt_small_photos number=”9″ arrows=”rectangular_accent” autoslide=”450″ loop=”true”][/vc_column][/vc_row]